Located at our head office in Eindhoven in the Netherlands, OSPL has a secure, clean and modern production facility staffed by a core team of experienced professionals.

The production facility is flexible in that it can easily be configured to build OSPLs full range of TEMPEST, rugged and secure products in small or large production batch sizes.

From start to finish the production cycle and certification is closely monitored according to the guidelines stated in ISO/IEC 17025, scope number L552, ensuring that we maintain the highest levels of quality and professionalism throughout.

Attention to detail and strict adherence to anti-static precautions ensure that you will receive a reliable product of the highest quality.

Once built, all equipment will undergo a full functional test.

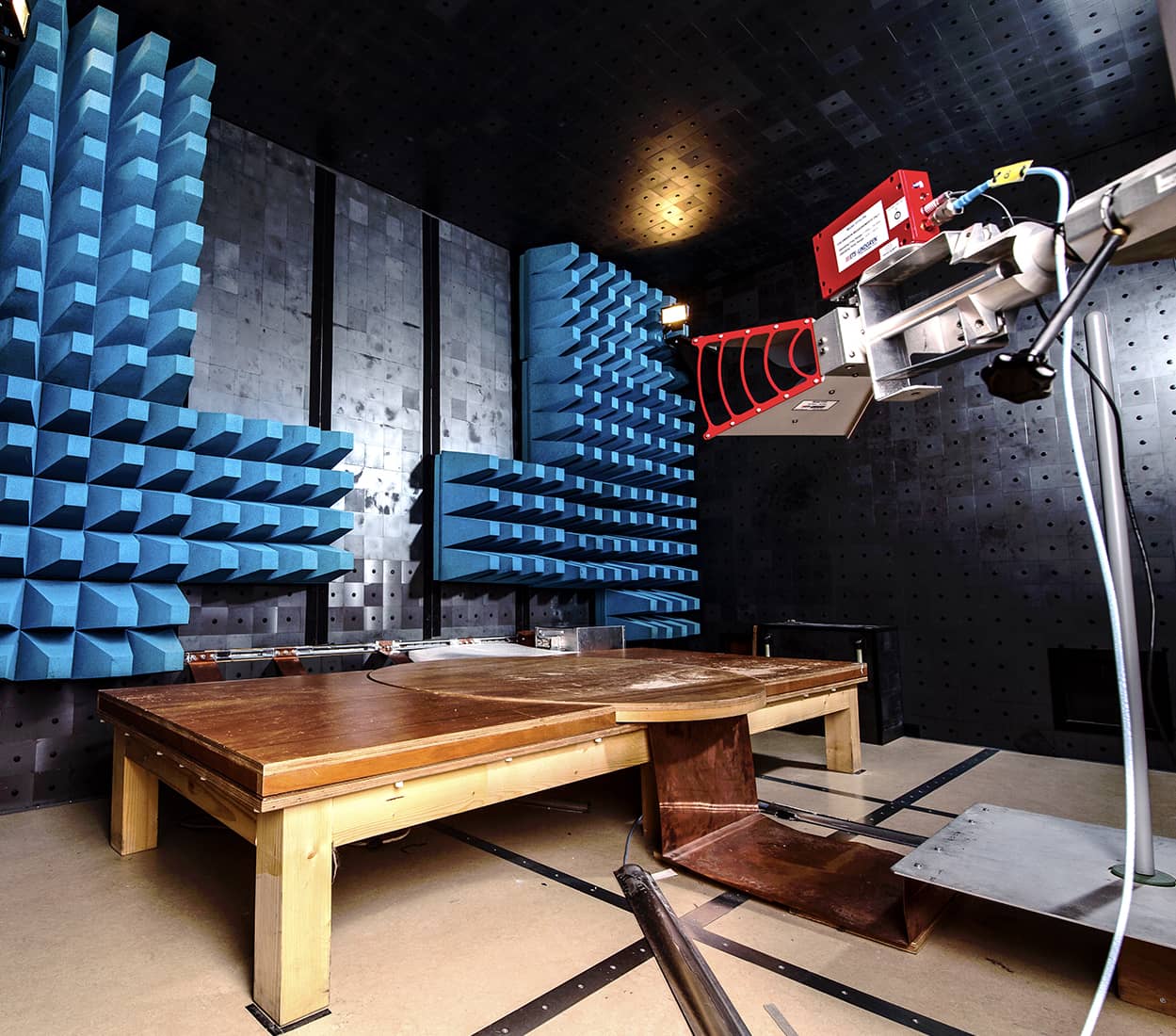

OSPL Nederland BV operates and manages a TEMPEST test facility according to the guidelines stated in ISO/IEC 17025, scope number L552.

The TEMPEST Test facility is equipped with the most modern and compliant TEMPEST test equipment.

OSPL currently has three accredited TEMPEST test chambers capable of performing TEMPEST compliance testing to both the NATO SDIP-27/2 and EU IASG 7-03 TEMPEST standards.

OSPL’s TEMPEST facility, per the requirements of NATO SDIP-55, is working according to the guidelines stated in ISO/IEC 17025, scope number L552. This guarantees that our procedures, methods and practices are regularly independently audited ensuring that all our TEMPEST test equipment is routinely calibrated and our TEMPEST test engineers remain trained to the highest levels.